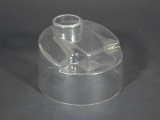

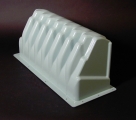

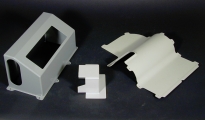

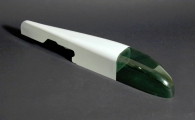

Vacuum Forming

Our vacuum forming capabilities include a variety of thermoforming machines, trimming/routing machines, CNC machining center, tool room for mold design/building, broad ‘secondary’ fabrication capabilities and CAD design are other in-house offerings.

Our sheet-fed machines allow custom production for station molding which can handle up to 8mm thick material in sheets as large as 3500mm x 1500mm.

Multiple inline thin gauge machines allow for around-the-clock operation and our inline machines can handle any material in roll form. Single part sizes can be as large as 760mm x 1100mm, but molds can be manufactured to accommodate multiple parts within that area allowing for greater production quantities in a shorter period of time.

Auxiliary operations include trimming, drilling, CNC machining, painting, pad printing, screen printing, sub-assembly, packaging, gluing and other manual operations.

Services:

– CAD and CAD/CAM

– Prototypes with our rapid prototyping program

– 4-6 week turnaround concept to final production

– In house mould and pattern making

Mold design and making:

– Custom wood and ‘constructed’ molds

– Patterns for aluminum molds

– Rapid prototyping with full part production

– International logistics

Quality control:

– ISO 9001 2000

Typical thermoplastic materials used:

- ABS – Acrylonitrile Butadiene Styrene

- PC – Polycarbonate

- PE – Polyethylene

- PP – Polypropylene

- PVC

- PET

- Acrylic (PMMA)

- Lexan ®

- HIPS – High Impact Styrene